Blast Freezer

Best Blast Freezer Manufacturer In Pune

Falcon Refrigeration Industry is renowned as the leading blast freezer manufacturer in Pune, providing superior quality products and exceptional customer service. Falcon Refrigeration Industry is committed to delivering the highest quality refrigeration solutions for all your commercial and industrial needs.

Simply put, the Blast Freezer is very cold. Blast cooler is sometimes called Blast Chiller. The idea of this type of freezer storage is to freeze food or fresh food very quickly. It is widely used in the frozen food industry for ice cream, side dishes, vegetables, and fish.

Many commercial kitchens also use a freezer. Falcon Refrigeration are world class Blast freezer manufacturers suppliers in Pune. Air Blast Freezer Manufacturers provide Blast Freezer for instant freezing.

How does the Blast Freezer work?

When food freezes, the water crystallizes into ice, and the longer the freezing process, the larger the ice crystals. These large crystals can damage the material by rupturing the cells and destroying the cells in the canned food. This often spoils the quality and taste of food by affecting the taste and texture of the food. However, Blast Freezer Manufacturers in Pune provide Blast Freezers for quick freezing. It forms very small crystals and it prevents damage, also preserves food of higher quality. Once the food is frozen in a blast freezer, it can be transferred to a regular freezer for long-term storage.

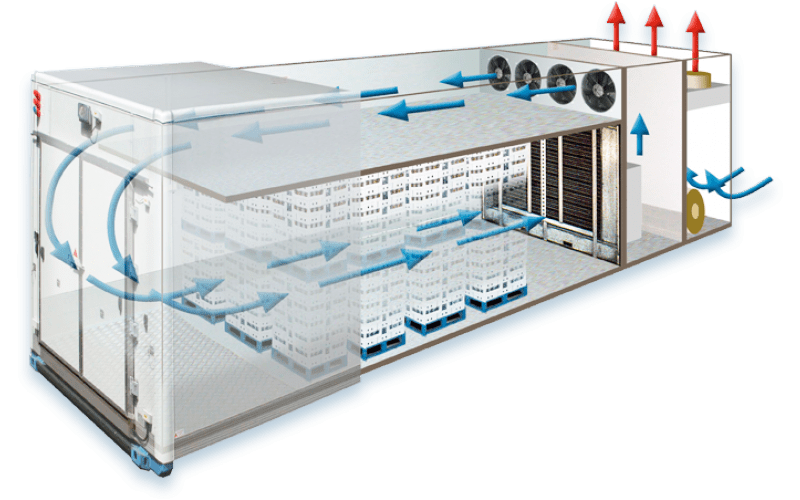

Blast Freezer typically uses a fan to send cold air to the contents of the freezer for rapid cooling. They can be fitted with moving trays for placing food and often include various compartments for freezing. Blast freezers can usually process food at room temperature or heat as long as the capacity is not overloaded. At Falcon Refrigeration we work as Air Blast Freezer Manufacturers and Industrial Blast Freezer Manufacturers.

A blast freezer works by rapidly freezing food products at a very low temperature, typically below -18°C. The process involves blowing cold air over the products at a high velocity, which helps to remove the heat from the food quickly. This rapid freezing process prevents the formation of ice crystals and preserves the quality of the food.

Blast freezers are commonly used in commercial kitchens and food processing facilities. They quickly freeze large quantities of food products. Such as meat, and fish goods. The danger of bacterial development and spoiling is also decreased by the quick freezing procedure.Blast freezers typically have a powerful refrigeration system. That can rapidly cool the air to the desired temperature. With a fan system to circulate the cold air over the products.

Some blast freezers may also have a defrost cycle to remove any ice buildup on the evaporator coils. Which can reduce the efficiency of the freezer over time. Overall, blast freezers are an essential tool for businesses that require efficient and effective freezing of food products.

How cold is the Blast freezer and how long does it takes to freeze?

Standard freezers are usually stored at 0 ° C, but flash freezing works at temperatures between 30 ° C and 40 ° C. Flash freezing extends the freezing process to about 3 hours.A blast freezer generally has a temperature range of -30 to -40 degrees Celsius. Which is much colder than a standard freezer. This ultra-low temperature allows for rapid freezing of food products. Frequently in a few hours or less, based on the size and thickness of the items being frozen.

The exact freezing time can vary based on several factors. Such on the food goods’ beginning temperature, the items’ size and shape, and the freezer’s storage capacity. However, the high velocity of the cold air in a blast freezer. Ensures that the food is frozen quickly and evenly. Which helps to maintain its quality and freshness.

Blast freezers are powerful refrigeration units that are used to rapidly freeze food products to very low temperatures. Blast freezers may freeze food in a couple of hours or even minutes. Unlike conventional freezers, which may take hours or days to accomplish so. We’ll talk about how blast freezers operate. How chilly they can become, and how long it takes to freeze food using this technology in this post.

How Blast Freezers Work:- Blast freezers work by circulating cold air at high velocities around food products. This rapid air circulation helps to remove heat from the products and quickly reduces their temperature. The cold air is usually generated by a refrigeration unit, which can be located either inside or outside the freezer. The air is then forced into the freezer by a fan, creating a powerful flow that rapidly cools the food products inside.

To use a blast freezer, food products are typically placed on racks or shelves inside the unit. The racks or shelves are designed to allow for maximum air circulation around the products. Ensuring that they are cooled as quickly and efficiently as possible. Once the products are loaded into the freezer. The unit is turned on and the temperature is set to the desired level.

What is the price of blast freezer room?

The price of a blast freezer room can vary depending on various factors such as size, insulation, cooling capacity, and features. Generally, freezer rooms are custom-built to meet the specific requirements of the user. The cost of a stainless steel blast room. Depending on the specifications and customization needed.

Other factors that can affect the price of a blast-freezer room include the type of refrigeration system. The type of door, and the type of flooring. The location and installation requirements can also affect the price. It is recommended to get a quote from a reputable blast freezer room manufacturer or supplier to get an accurate estimate of the cost.

What is another name for blast freezer?

A blast freezer is a type of freezer that rapidly freezes food or other perishable items to preserve their quality and freshness. It is also known as a shock freezer. Which refers to the sudden and extreme cooling process that takes place inside the freezer. The term “shock” is used because rapid cooling helps to shock the food. Preventing the formation of ice crystals and maintaining the texture and flavor of the food.

In addition, blast chiller freezers are often used in commercial kitchens, bakeries, and food processing plants to quickly freeze large quantities of food. While also allowing for more efficient storage and transportation. So, whether you call it a blast freezer in Pune or a shock freezer.

What is the difference between freezer and blast freezer?

What is the coldest Blast Freezer?

Benefits of Blast Freezer :

- Instant freezing guarantees the nutritional value, taste, texture, and color of the food to be stored

- The appearance of the food is protected from damage and dehydration by the ice skin formed on the surface as a result of the instant freezing

- Instant frozen foods are safe because they prevent the growth of microorganisms.

- Instant frozen foods maintain their structure and quality.

- The instant freezer contains different compartments for each food. The risk of contamination is low

- Instant freezing is beneficial. It can store a large number of products, so it is cooked. This is ideal for retaining leftovers and reducing food waste.

Blast Freezer Application

Blast Freezer is a commercial freezer made exclusively for business owners. Due to increased production and demand for products, these products need to be frozen. Here are some of the uses of the shock freezer: They are widely used in the food industry for rapid freezing of various food products. The fast freezing process helps to maintain quality, texture, and freshness. The food items, while also prevent bacterial growth and reducing the risk of spoilage. Here are some common applications of blast freezers:

Food Processing: Blast freezers are commonly used in food. Processing facilities for rapid freezing of meat, poultry, seafood, and baked goods. This helps to maintain the items’ quality while extending the shelf life of the goods.

- There is an industrial blast freezer used in commercial facilities such as refrigerated warehouses, Commercial kitchens, large restaurants, hotels, etc. use shock freezers and shock chillers to safely store groceries, cooked food, and food. Blast chillers cool large amounts of food by blowing a very cold breeze over the entire storage space. It removes harmful bacteria from the food supply and preserves them. If you have to serve from it over and over again with a sudden notice, you can put a large amount of food in such a cooler.

- Blast Freeze is also used in confectionery to store large amounts of desserts/pastries that need refrigeration, such as pies, cakes, puddings, and ice cream. Proper refrigeration improves the taste and texture of desserts.

- The fish industry and meat suppliers are widely used in shock-freezers. If not properly stored, seafood quickly spoils. To deliver raw fish and shellfish to distant markets around the world without compromising transportation quality, storing fish and shellfish in such freezers prevents long-term inventory degradation. The vaccine contains drugs that are used to stimulate an immunogenic response when given to a patient. Maintaining the stability and viability of the active ingredient during vaccine production, distribution and administration is a major challenge for vaccine manufacturers. When stored in a shock freezer, the decomposition of the active ingredient is greatly reduced, making it more stable and durable.

- The dairy industry uses blast chillers to store large quantities of dairy products (curd cheese, butter, milk, flavored milk, clarified butter, cottage cheese, etc.) so that they can be shipped to remote locations without loss Of quality.

- Food Processing: Blast freezers are commonly used in food. Processing facilities for rapid freezing of meat, poultry, seafood, and baked goods. This helps to maintain the items’ quality while extending the shelf life of the goods.

- Commercial Kitchens: Restaurants and other food service businesses. To quickly freeze cooked or raw food items. Reducing waste and ensuring that ingredients remain fresh.

- Ice Cream and Frozen Desserts: Freezers are used to rapidly freeze ice cream and other frozen desserts. Ensuring that they maintain their texture and flavor.

- Pharmaceutical Industry: Some pharmaceutical products require very low temperatures for storage. Freezers can be used to quickly freeze these products and maintain their quality.

- Research and Development: Freezers are used in research and development labs. For freezing and storing samples, and specimens. Some other materials require low temperatures for preservation.